| Inner Dimensions (D x H) |

400x600mm |

400x1100mm |

500x900mm |

500x1200mm |

| Inches Conversion |

16 x 24 |

16 x 44 |

20 x 36 |

20 x 48 |

| Capacity |

88 ltrs |

162 ltrs |

165 ltrs |

220 ltrs |

| Working Load |

6.0 KW |

6.0 KW |

9.0 KW |

10.0 KW |

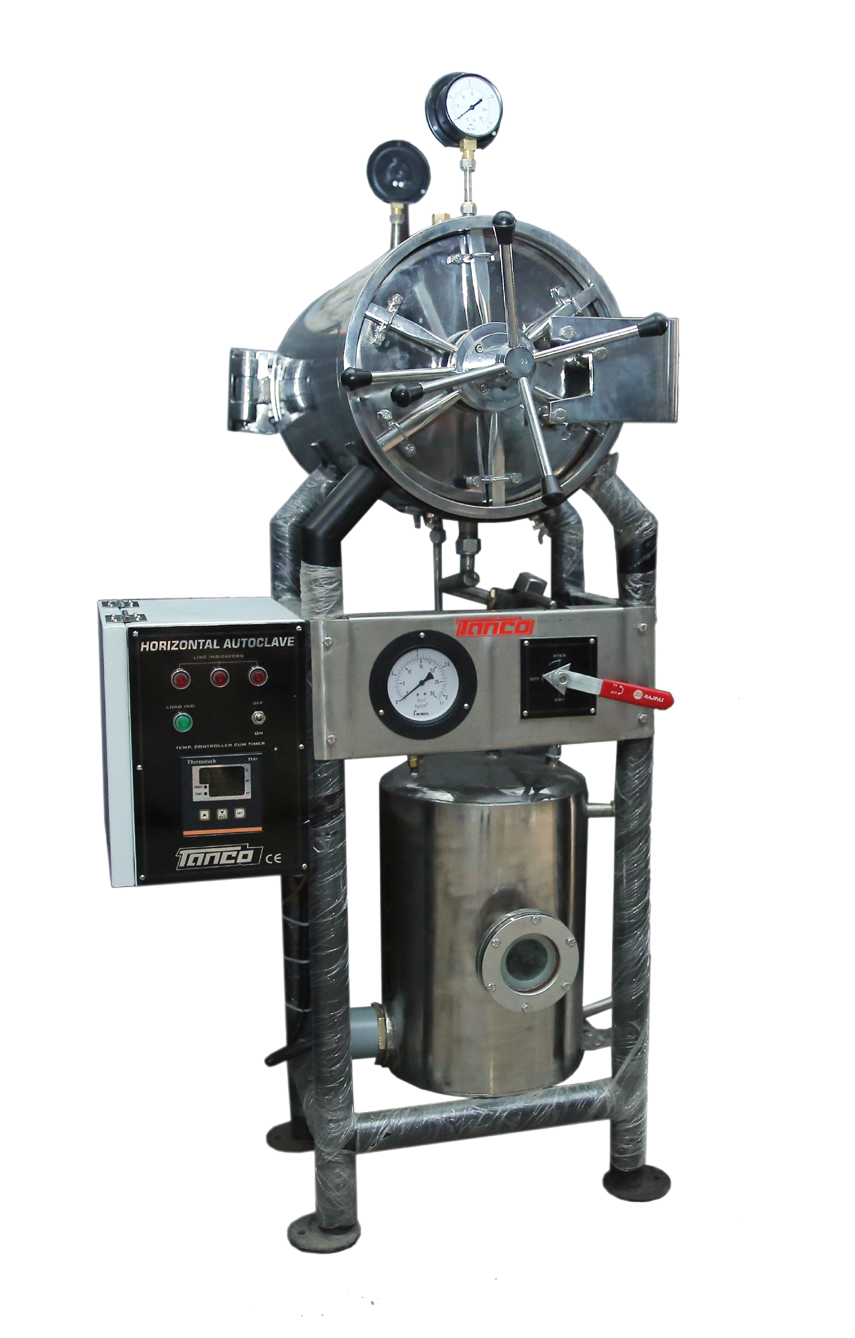

| Pressure Gauge |

0-30 psi |

| Working Pressure Gauge |

10-20 psi |

| Gasket |

Made of Neoprene Rubber |

| Sterilizing pressure |

1.2 kgf / cm (15psi)at 121°c |

| Pressure Gauge |

0-2.1 kgf / cm² (30 psi) |

| Operating pressure |

From 15 to 20psi (Adjustable) |

| Inner Pressure Tank |

Stainless Steel (SS-304) |

| Lid Quality |

Heavy mild steel sheet lined with Stainless steel |

| Basket |

Made of Stainless Steel |

| Lid Tightening |

Radial Locking system worked by handle |

| Water Level Indicator |

Fitted on the outer chamber |

| Boiler – Hydraulically Tested |

Upto +40 psi |

| Accuracy |

+ 3 psi |

| Safety Device |

Spring Loaded Type |

| Water Draining System |

Hand Operated Valve |

| Heating |

BY ISI Marked Immersion Heaters |

| Steam & Vacuum Release |

By Valve |

| Power Supply |

440 volts, 3 phase A.C. Supply |